Dynabolts are a type of bolt commonly used in construction and similar industries for securing structures to concrete or masonry surfaces. These versatile & durable fasteners are designed to provide a strong and reliable hold to the base material, making them an ideal choice for different applications. Whether you’re building a new home, installing equipment in a factory, or securing a sign to a wall, dynabolts are a proven and reliable solution. In this article, we will take a closer look at dynabolts, including their types, advantages, and installation process, to help you understand why they’re an essential tool for any construction project.

What is a dynabolt?

A dynabolt is a general purpose all steel medium duty through fixing for masonry and concrete. It is one of the types of sleeve anchors that feature a split expansion sleeve over a threaded stud bolt body and integral expander, nut and washer. In order to anchor it to the base material, torque is applied at the nut or screw of the dynabolt, where an internal expander causes the expansion sleeve to expand & grip the hole tightly.

Dynabolts are pre-assembled & rated for heavy loading. They also come in different head styles, finishes, & sizes.

Types of Dynabolts

Dynabolts come in different variants. Typical differentiation features are the head type & material used.

Head Types of Dynabolts

Commonly dynabolts are manufactured with 7 different head types.

Hex Nut Head

A dynabolt with a hex nut head features a split expansion sleeve over a threaded stud bolt body and integral expander, with a nut and washer as the head. Having the nut as the head allows for easy toque application with the simple use of a wrench or any type of spanner to anchor the dynabolt.

Hex Bolt Head

A dynabolt with a hex bolt head is mostly similar with a hex nut head dynabolt, with the only difference being that a hex head bolt takes the place of the nut & washer in the dynabolt’s head. Having a hex head means that the dynabolt will be fastened permanently in its location. Preferably, a washer should still be added under the hex head, in the event the base material is soft to prevent deforming.

Countersunk/ Flat Head

Countersunk/ flat head dynabolts give the main benefits of a dynabolt, while leveraging their countersunk head design to put the head flush with the surface. This allows the area to have an aesthetic finish. They don’t stick out of the surface, avoiding catching other things on it. A screw driver is used to drive this type of dynabolt to fasten it to the base material.

Round Head

Bolts with round heads are commonly used in wood connections. This means dynabolts with round heads are commonly fastened on wood, while being anchored in masonry or concrete. A screw driver is also used to drive this type of dynabolt to fasten it to the base material.

Hook Head

Regular hook bolts are steel fasteners that are similar in shape of the top part of a question mark. These “hooks” are usually used to hang items from ceilings and walls, & they have an open end to make it quick & easy to remove & rehang items. Combining this “hook” with the body of a dyna bolt allows one to the benefits of a hook bolt in ceilings & walls made of masonry or concrete.

Eye Head

Regular eye bolts have a loop at one end, which is used to tie ropes or cables to it. Dyna bolts with eye heads allow for ropes & cables to be tied to it, while leveraging the sturdy base materials dynabolts are usually fastened to.

Tie Wire Head

Tie wire thru-bolt anchors are usually employed for tasks including suspending ceilings, fastening cable ties, supporting wires, and installing ducting systems. Longer variants aid in situations where insulation panels have been installed.

Different Materials of Dynabolts

Zinc plated carbon steel

One type of material dynabolts are manufactured from is zinc-plated carbon steel.

Zinc plating, otherwise known as electro-galvanizing, is where zinc is applied with the use of a current of electricity. Its thin coating provides some rust protection, but it is not as resistant as hot dip galvanizing. Main advantages of zinc plating is cheaper costs & ease of welding.

Carbon steel is steel with carbon content from ~0.05 to 2.1% by weight.

Zinc plated dyna bolts are typically used in applications such as:

- Shelf ledgers

- electrical boxes

- Conduit

The environment these are used are typically indoors (to minimize corrosion), and its level of corrosion is low.

304 Stainless Steel

Grade 304 stainless steel is the most commonly used austenitic stainless steel. Austenitic alloys have high nickel and chromium content, which makes the steel they are used to create exceptionally corrosion-resistant.

304 stainless steel dyna bolts are typically used in environments like:

- Cladding

- Brick ties

A slight to moderate degree of pollution is permitted in the environment these dyna bolts are used, & the level of corrosion of this dynabolt is medium.

Advantages of Using Dynabolts

The main advantage of using a dynabolt is that it is a a high-performance anchor with minimal insertion energy needed for quick mounting. The fastening may be driven in with reasonably minimal force, which enables a force-saving installation procedure. Additionally, a high shear stress resistance is made possible by the optimal contact between the screw shank and anchor sleeve, & friction locking is used to securely engage the loads into the base material.

Other benefits of using dynabolts include:

- Anchor diameter equals hole diameter

- Versatile – 6 different other head styles as variants

- Different sizes available for different applications

- Different materials for different applications: Zinc plated carbon steel and 304 stainless steel

- Provides full 360° hole contact over large area and reduces concrete stress

- Heavy-loading capacity

- Preassembled for faster, easier installations

- Dynabolt can be installed through object to be fastened

- Sleeve design improves holding power

- No pre-spotting of holes necessary

How to Use Dynabolt

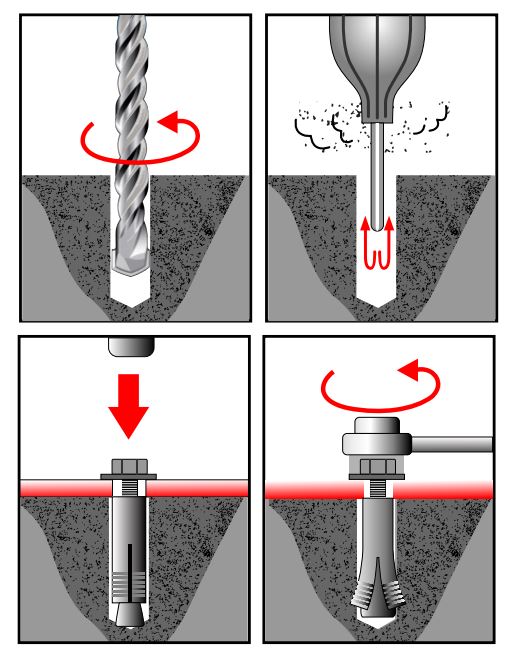

- Drill a hole.

- Clean hole with pressurized air/ vacuum & brush.

- Lightly hammer dynabolt into hole until nut and washer makes contact with the base.

- Tighten nut to expand expansion sleeve & anchor in base material.

Precautions of using Dynabolts

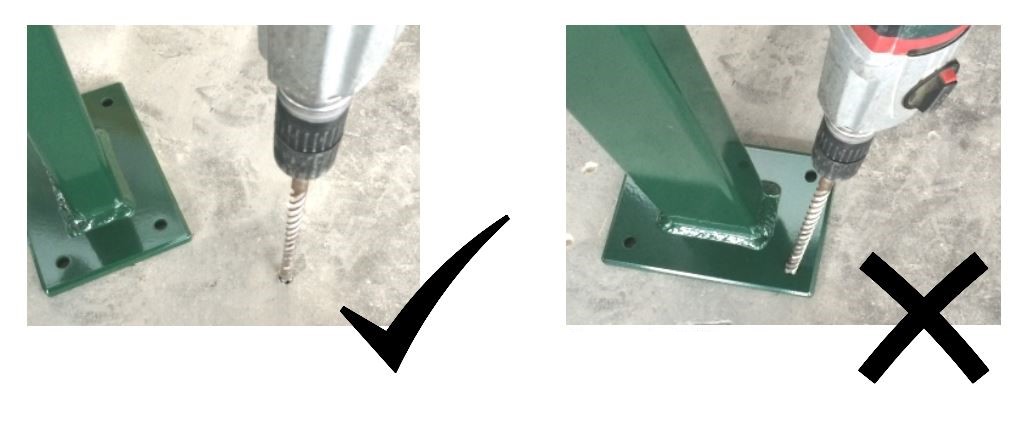

No hole drilling through base plates

Mark hole positions using product base plate. Move product aside to drill concrete holes.

In the absence of a hand pump, compressed air or vacuum, use the drill to clean out concrete holes, while brushing debris away each time, a minimum of 2 times.

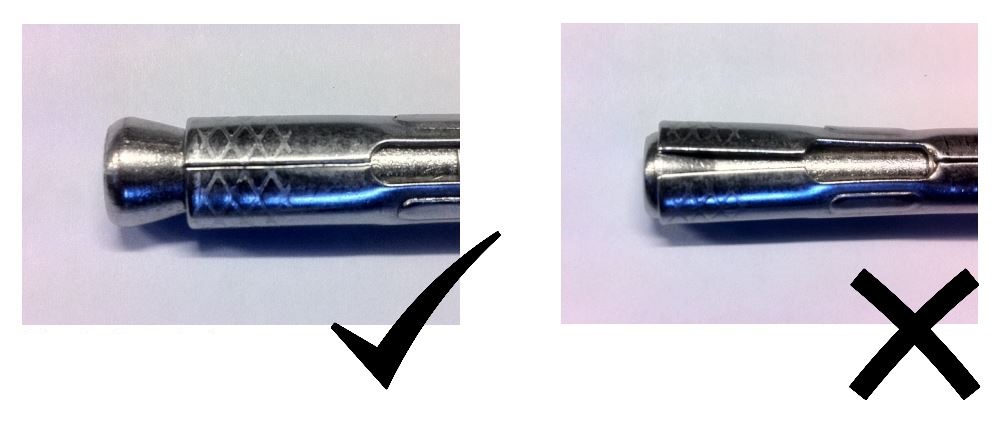

Check Dynabolt isn’t expanded

Check the dynabolt expansion sleeve is free from the bottom of the bolt to ensure the sleeve is not expanded beyond 10mm in diameter.

Anti-tamper armour rings

Following successful placement of the product, with dynabolts secured, place the armour ring over its head.

Ensure product placement is correct. This will make removal very unlikely due to accidents.

Tap into place with a soft faced hammer.

Conclusion

Dynabolts are powerful & reliable for securing structures to concrete or masonry surfaces. They come in a variety of forms, each with its own set of head types, features, & uses, making them suitable for different applications. By using dynabolts, you can ensure that your construction project is built to last, while also saving on time and cost. With their superior strength & durability, dynabolts are the ideal choice for any construction or industrial application. Whether you’re a professional contractor or a DIY enthusiast, it’s worth considering dynabolts as your go-to fastening solution.

Helix Steel Products Corporation supplies dynabolts for different Philippine contractors & construction companies, and our fasteners have been used in different national projects such as the Skyway Stage 3 & the LRT-2. If you are interested to have dynabolts supplied for your next project, reach out to us by emailing hspcmarketing@gmail.com or calling us at 09774562420.