Material: Zinc Plated Carbon Steel

This specific dynabolt uses a zinc plating finish, also known as electro-galvanizing, is the application of zinc using an electrical current. Although it has a thin coating, it does some rust prevention, although not as well as hot dip galvanizing. Zinc plating’s primary benefits are lower prices and simplicity of welding.

Carbon steel is steel with carbon content from ~0.05 to 2.1% by weight.

Zinc plated dynabolts are commonly used in scenarios such as:

- Shelf ledgers

- electrical boxes

- Conduit

These anchors are primarily utilized indoors (to reduce corrosion), and there is little corrosion present.

We also have these in a stainless steel finish.

Key Features

A dynabolt’s primary benefit is that it is a high-performance anchor that requires little insertion energy for fast mounting. The fastener can be installed using less force than necessary because to its ability to be hammered in. The ideal contact between the screw shank and anchor sleeve also allows for a high shear stress resistance, and friction locking is used to securely engage the loads into the base material.

- Anchor diameter equals hole diameter

- Available 1/4 – 1” diameter & 2” to 6 1/4” length

- Different materials for different applications: Zinc plated carbon steel and 304 stainless steel

- Zinc plated carbon steel offers decent rust protection indoors

- Provides full 360° hole contact over large area and reduces concrete stress

- Heavy-loading capacity

- Preassembled for faster & easier installations

- Can be installed through object to be fastened

- Sleeve design improves holding power to base material

- No pre-spotting of holes necessary

How to Use Dynabolt

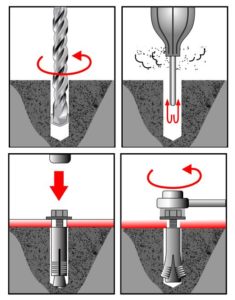

- Drill a hole

- Clean hole with pressurized air/ vacuum & brush.

- Drive the dynabolt into hole until nut and washer makes contact with the base.

- Tighten nut to expand expansion sleeve & anchor in base material.

Technical Specifications

Dynabolt Sizes | Sleeve Length (mm) | Drill Diameter (mm) | Fixing Length (mm) | Sleeve Anchor SIzes | Recommended Torque ft/lb | Put Out Load (lbs) | |

1/4" x 2" | 30 | 9.5 | 6.5 | 8 | 6.5 x 36 | 5 | 2,600 |

5/16" x 2 1/2" | 35 | 12.0 | 6.5 | 28 | 6.5 x 56 | 8 | 1,560 |

3/8" x 3" | 40 | 14.5 | 8.0 | 12 | 8 x 40 | 15 | 3,360 |

1/2" x 4" | 50 | 18.0 | 8.0 | 37 | 8 x 65 | 25 | 6,040 |

5/8" x 4" | 50 | 22.0 | 10.0 | 12 | 10 x 50 | 50 | 5,000 |

5/8" x 5" | 60 | 22.0 | 10.0 | 15 | 10 x 60 | 50 | 5,000 |

3/4" x 6" | 80 | 26.0 | 10.0 | 39 | 10 x 77 | 90 | |

1" x 8" | 110 | 33.0 | 33.0 | 27 | 12 x 75 | ||

Common Applications

- Anchoring into concrete, hollow concrete block, & grout-filled concrete block

- Anchoring to brick base materials.

- Timber to concrete, form work, battens, bottom plates

- Services – ductwork, pipes brackets, cable trays, suspended ceilings.

- Metalwork – signs, hand rails, gates.

Frequently Asked Questions

What is a DynaBolt used for?

Dynabolts are generally used to anchor to concrete, hollow concrete blocks, grout-filled concrete blocks, & brick base materials. It also has other uses for timber, duct works, & metalworks.

What is a Dino bolt?

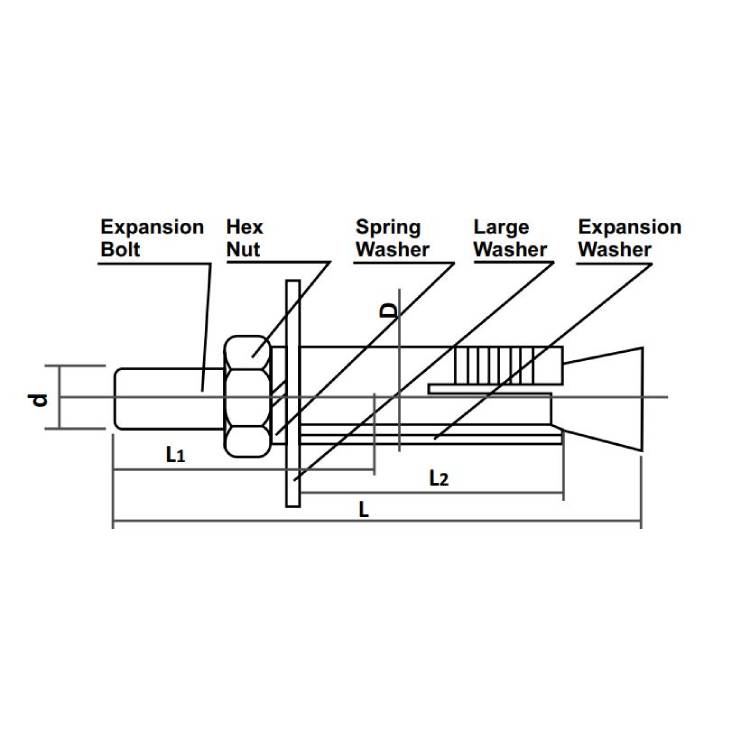

Dynabolts are a universal, medium-duty through fastening for masonry and concrete made of steel. It is one of the varieties of sleeve anchors that has an integral expander, nut, and washer over a threaded stud bolt body with a split expansion sleeve on top. This anchors it to the base material.

These sleeve anchors are pre-assembled and have a high loading capacity. They are also available in a variety of sizes, finishes, and head designs.

How do you secure a DynaBolt?

When torque is applied to the nut or screw of the dynabolt, an internal expander allows the expansion sleeve to expand and firmly grip the hole. This anchors it to the base material.

How strong is a DynaBolt?

Technical specifications indicate that dynabolts can manage 2,600 lbs. (11.57 kN) – 5,000 lbs. (22.24 kN) in Put Out Load.