Are you overwhelmed by the different types of bolts and nuts and washers available?

Bolts, nuts and washers are some of the most common industrial fasteners in use. The same task is carried out by all fasteners: connecting and fastening two or more components mechanically. The performance and service life of the fastener, however, are considerably impacted by variations in type, quality, shape, and material. To choose the right fastener (and fastener provider) for your project, it is crucial to comprehend the functional variations of the various types accessible, including nuts, bolts, and washers.

However, the job is not always easy, as there is just so much bolts, nuts, and washer variants manufactured and in the market that it’s enough to make a new engineer or project manager overwhelmed to choose for their next project. So, here is a comprehensive guide on more than 30 different types of bolts and nuts with pictures. Bookmark this article, and make sure to reference this page whenever you are deciding which bolts and nuts to buy.

Kinds of Bolts

Carriage Bolts

Carriage Bolts provide simple installation and versatility when assembling a variety of building materials, not only with hardened steel, but also for softer materials like wood & plastic. They are designed with a smooth, large diameter head that resists pull-through in softer materials and a square neck that prevents the bolt from turning when tightening the nut.

Flange Bolts

Flange bolts have a round flange beneath the head that distributes the load like a washer. Because of this feature, it’s the preferred choice for metal to metal fastening.

Plow Bolts

Plow bolts commonly have a square neck, to stop the bolt from rotating as it is being tightened, and a flat head, where the head of the fastener is subjected to excessive amounts of wear. These fasteners are frequently used in farm machinery, heavy machinery for building roads, and other equipment.

Hex head bolts/ Hex Head Cap Screw

Hex bolts, sometimes called hex capscrews or machine bolts, are structural fasteners that have hexagonal heads and machine threads. They’re meant to be used with a nut and washer as part of a total fastener assembly. They may also be installed directly into a tapped hole.

Square Head Bolts

Square head bolts are utilized in applications where strong fastening is needed but visibility is restricted. These bolts are simple to tighten with a wrench and have large, flat sides. Square heads work best in small, dim areas where a fabricator or machinist must blindly tighten the bolt. Even without any visible marks, it is easy to fit a tool across the square head, reducing the likelihood of tool slippage.

Socket head cap screws/ Allen Bolt

Threaded fasteners with a recessed hexagon drive and a cylindrical head are known as socket head cap screws. Socket screws, also referred to as Allen head screws, are tightened to far greater torque standards than a crossed recessed or slotted drive fastener. They are twisted using a hexagon-shaped key, also known as Allen wrenches, hex-key wrenches, or hex keys. In circumstances where there is not enough clearance to utilize a fastener with an exterior hexagon head, socket head cap screws are frequently used.

Round Head Bolt

For wood connectors, button head or round head bolts are frequently used. round head bolts resemble carriage bolts but lack the square neck that surrounds the head. Round head bolts are rarely high strength and almost always offered in a basic ASTM A307 specification because they are frequently used with wood.

T Head Bolt

T-Head bolts are typically used with nuts to link an object with a T-shaped groove such that the bolt head fits flush or below the material surrounding it.

J Bolt

The J bolt, which is frequently viewed as half of a U bolt, has a long threaded part and a smooth curve that can both be used to fasten objects in place. Because of its adaptability, the J bolt can be utilized in a variety of situations, such as the automobile, locomotive, and building and construction sectors. It is also used in household settings for do-it-yourself projects like hanging baskets and deck building.

U-Bolt

A “U”-shaped curved bolt having threaded holes on both ends is known as a “U bolt.” In addition to being employed in a variety of building and construction applications, these fasteners are used to support piping. These fasteners are used in piping support, as well as in various building and construction applications.

Eye Bolt

Mainly used in an assembly to lift or suspend a load (usually a machine), eye bolts are characterized by a loop in one end & a threaded rod on the other.

Shoulder Bolt

Shoulder screws have integrated threads that only cover half or less of the screw shank. The head, shoulder, and thread are its three component parts. The screw’s head, which has the greatest diameter part and serves as both a bearing surface and a drive mechanism (slotted, hex, etc.) for installing it, prohibits the screw from being inserted any further than its length. The center, smooth region of the screw called the shoulder is where the workpieces’ lateral movement is contained. The threaded portion contains helixed grooves with a main diameter that is only marginally smaller than the shoulder diameter. This section is for insertion into a matching thread, such as a nut or tapped hole

Cylindrical Head Bolt

Mainly used in clamping engine cylinder heads to engine blocks.

Elevator Bolt

Canvas belts used in grain elevators and other conveyer systems are held together by elevator bolts. To prevent the bolt from passing through the soft conveyor material, a larger bearing surface is created by the large diameter of the head and square neck.

Hanger Bolt

Hanger bolts have machine threads on one end & wood threads on the other.

Lag Screw/ Bolt

Lag screws, sometimes called a lag bolt, are similar to hex head bolts, with the only difference that it has wood threads instead of machine threads. Because of this, they are mainly used in heavy lumber & similar materials to bear a heavy load.

Cylindrical or cheese-headed bolt

“Cheese head” screws are identified by what their head looks like. The cheese head has flat disc top and bottom surfaces, as well as cylindrical sides. The head height usually features a slot drive and is roughly half the diameter.

Countersunk-headed screw/ bolt

A countersunk screw, often referred to as a flat-head screw, is a specific kind of screw that is intended to lay flush with the item or surface into which it is placed. Because they “sink” into objects and surfaces, they are known as “countersunk screws.” They have a flat head that tapers along the shaft. Railing, walkways, and bridge decking are typical applications.

Threading can either be wood or machine threads.

Stove bolt

Stove bolts are frequently used in the installation of wood-burning stoves. They are made of sheet metal & have a slotted head. Because they have a machine thread and a round, flat, or truss head, stove bolts are occasionally referred to as machine screws.

Hook Bolt

Hook bolts are bolts with a hook at one end and a threaded hole for a nut at the other.

Dynabolt

A dynabolt is a general purpose all steel medium duty sleeve anchor mainly used for masonry and concrete, and it features a split expansion sleeve over a threaded stud bolt body and integral expander, nut and washer. In order to anchor it to the base material, torque is applied at the nut or screw of the dynabolt, where an internal expander causes the expansion sleeve to expand & grip the hole tightly.

We have written a more comprehensive guide about dynabolts available.

Expansion Shield

A die cast zinc alloy expansion shield called the Expansion Shield is used to attach lag screws in a range of base materials, including concrete, concrete block, brick, and mortar joints. In softer materials, radial ribs give additional holding strength.

Rag foundation bolt

This distinctive foundation bolt has a square or rectangular cross-section, a tapered body, and grooves on all four sides. Rag bolt installation must be completed before the entire assembly can be set in concrete.

Stud bolt

Stud Bolts are solid bars with a circular cross section that is fully threaded. They are used with 2 hexagonal nuts to commonly connect flanges for pipeline, drilling, petroleum / petrochemical refining and other industries requiring sealing and flange connections.

Kinds of Nuts

Coupling nuts

Coupling nuts, commonly referred to as extension nuts, are threaded fasteners used to connect two threaded rods. The hexagonal exterior of these nuts enables safe tightening and loosening with an installation tool.

Flange nuts

A hex flange nut is basically a nut with a built-in flange underneath it. The smooth bearing surface of the flange acts like a built-in washer, distributing the clamp load wider away from the nut, replacing a traditional nut and washer assembly.

Hexagonal/ hex nuts

Hex nuts have six sides. When no “locking” mechanism is needed, these nuts with internal threading are frequently used with machine-threaded bolts and screws.

Lock nuts

Lock nuts have a built-in mechanism inside the nuts to prevent itself from loosening from vibrations. There are different variations of lock nuts:

- Nylon lock nuts (Pictured here)

- Metal Locking Nuts

- Aerotight Nuts

- Shear Nuts

Slotted nuts

Slotted nuts have grooved heads that fit into holes in the bolt when they are joined, allowing for the cotter pin to be inserted and holding the nut in place. They are utilized in situations when the locknut might become loose due to vibration or motion.

Castle nuts

In contrast to slotted hex nuts, castle hex nuts have cylindrical slots that are roughly equal in length to the depth of the slot and somewhat smaller in diameter.

Square nuts

A square nut is a four-sided nut that is often used with square-headed bolts. Square nuts, as opposed to traditional hex nuts, provide a larger surface area in contact with the part being fastened and hence offer more resistance to loosening.

Wheel nuts

A wheel nut, also known as a lug nut, is a fastener that is used to hold a wheel to a vehicle. Typically, these nuts are found on cars, trucks, and other sizable rubber-tired vehicles. The majority of aluminum and steel wheels employ wheel nuts, which have with one rounded or conical (tapered) end. A set of wheel nuts is typically used to fasten a wheel to threaded wheel studs and subsequently to the axles of a vehicle.

Cap Nut

A nut with a domed end on one side is referred to as a cap nut. When paired with a threaded fastener that has an exterior male thread, the domed end encloses the external thread to either protect it or keep it away from neighboring items. The dome also creates a more polished appearance. There are different types of cap nuts, such as acorn nuts (where the domed side is pointed and has a taller crown)

Capstan Nut

A capstan nut has holes drilled laterally in the curved surface and is cylindrical in shape. For turning the nut, a tommy bar can be inserted into the holes.

Knurled Nut

A nut with a knurled outside surface is known as a knurled nut. This makes it easier to secure the nut into a handle (insertion nut) or cover or to tighten it by hand (thumb nut) .

Wing Nut

A wing nut, also known as a butterfly nut, is a type of nut having two sizable metal “wings,” one on each side, making it simple to tighten and loosen by hand without the use of any tools.

Kind of Washers

Beveled washers

Beveled washers are a unique kind of washer that have a flat side and a slanted side. Different installation angles can be accommodated by the sloped side, which also enables a stable and tight fit when mating and aligning two non-parallel faces.

Flat washers

When a screw or bolt is tightened, flat washers uniformly distribute pressure. Its thin, plate-like design increases surface area to stop a fastener from loosing and pulling out. Additionally, they reduce surface friction and serve as spacers when extra distance between items is required.

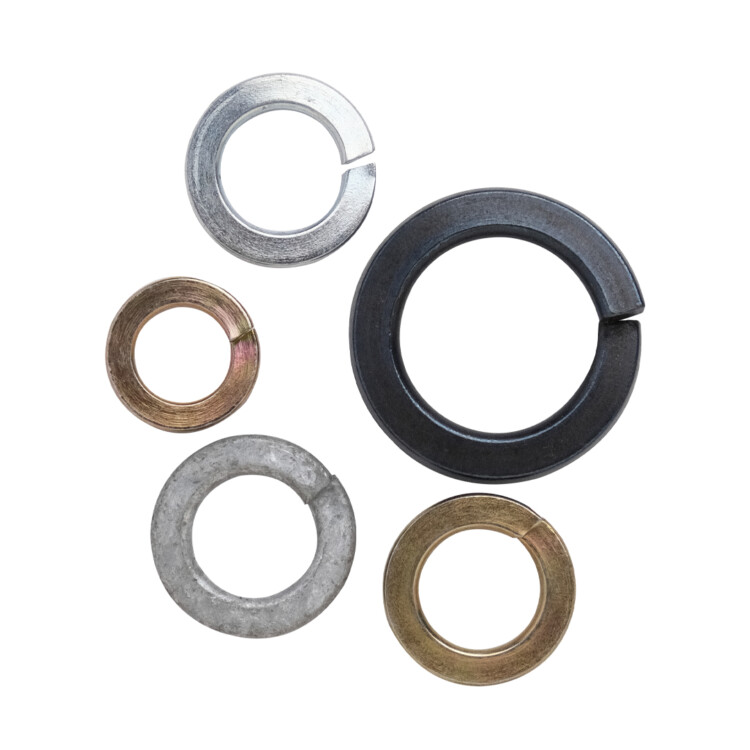

Lock washers

Lock washers are made to be tightened to the necessary torque just below a regular fastener. The fastener is prevented from vibrating loose by the spring tension they apply. They are frequently fastened to the fastener’s nut side.

Structural washers

When used with high-strength fasteners, structural washers are thick, heavy-duty, and designed for mechanical and structural applications. They are frequently found in steel-to-steel couplings for bridges, structures, and other infrastructure.

Uses of Bolts and Nuts

Industrial fasteners like bolts and nuts are commonly used in different industries, such as:

- Construction and building

- Manufacturing

- Plumbing

- Fire Protection

We commonly service these industries, but they are also used in much more industries than you think.

Conclusion

So, there you have it. This is a comprehensive guide to the different bolts and nuts and washers available & commonly used in different industries. Feel free to bookmark this article and refer back to it whenever you need to figure out the industrial fasteners you need for your next project.

With over 50 years of experience, Helix Steel Products Corporation is one of the leading Philippine manufacturers of industrial fasteners, which are currently being used in national projects like the LRT Line 2 & Skyway Stage 3. If you are looking for high quality, cost effective industrial fasteners, don’t hesitate to reach out to us by emailing us at hspcmarketing@gmail.com or calling us at 09774562420.

FAQs

What are the different types of nut and bolts?

Some bolt types include hex head bolts, square head bolts, u bolts, and eye bolts. Some nut types include coupling nuts, flange nuts, square nuts, and cap nuts. This guide will tell you about more than 30 different types of bolts and nuts and washers, as well as some of their applications.

What is the most common type of bolt?

Hex head bolt.

Whenever one mentions a bolt, the hex head bolt comes to mind because it is commonly machine screwed and has a hexagonal head, which makes it easy to use with common tools like wrenches.

How many types of bolt are there?

There are 23 types of bolts listed in this comprehensive guide.

Which is nut and which bolt?

A bolt is a type of threaded fastener that has an external male thread that requires a pre-formed female thread that matches, like a nut. A nut is a fastener having a threaded hole that serves as the female counterpart of the bolt. To secure many parts together, nuts are typically used in conjunction with a matching bolt.

Sir your article well defines major fasteners. in the first time I saw 24 types of bolts. describe in short and in simple language.

.it was worth the description is written. Thanks a lot, valuable sharing

Cheers

Hi Sanjay, thanks, and hope it was useful! 🙂